Home > Technology TOP > Embossing Technology

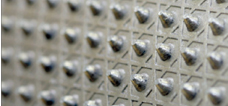

Improves the designs of the products; upgrade of appearance and texture

Provides the functions to the products; Thermal-bonding,bulking, cleating, anti-sticking, making holes etc.

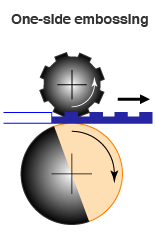

Combination of embossing roll and elastic roll(woolen paper,rubber etc.)Useful for embossing of shallow patterns on the surface of papers textiles films and so on.

Combination of embossing roll and steel roll(plain surface).

Useful for thermal-bonding of non-woven fabrics.

Coupling of embossing roll and woolen paper roll. Transferring the pattern of embossing roll to the surface of woolen paper roll, obtain a couple of the embossing pattern. Useful for embossing of deep pattern for papers. textiles, films and so on.

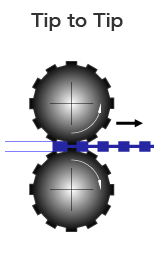

Coupling of embossing roll and embossing roll. The embossing patterns of two rolls are matching each other.Indispensable for bulking up of cushion sheets and embossing of steel plates.

Coupling of two embossing rolls which have the same embossing pattern and in phase each other. This process provides the products which do not have a right and a wrong side.

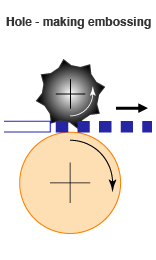

Combination of embossing roll engraved sharply and elastic roll. This process enables to make holes on films etc.

※ For questions, please feel free to contact us.

There is three methods of engraving embossing rolls as follows, According to the shape,roughness,depth etc,of embossing pattern,engraving method is selected out.

Typical method for engraving embossing rolls which use a mother roll called "mill" A mill is engraved by its prototype. called "die". Therefore, a die and an embossing roll have a same pattern. and a mill and embossed products have a mirror image of the embossing pattern. A die as a prototype is made by handwork or the special machine tools.

partially coating with light carable resin, corroding by etching make an embossing pattern on the roll surface.

Typical method for engraving embossing rolls whick use high-precision CNC lathe, High-precision CNC lathe directly engraves embossing rolls according to computer software of embossing

patterns, This is the newest method for engraving embossing, The following are strong points of this method.

・This method achieves high-precision engraving

・This method can engrave deep pattern in short term.

・This method can engrave part of roll's circumference.

・This method can engrave complicate 3D solid.

・This method can engrave coupling of two embossing rolls correctly.

※ For questions, please feel free to contact us.